Smyth sewn also known as section sewn book bindings are the highest quality book binding available on the market today it is the hallmark of library quality archival safe books because the pages are physically sewn into the book using binders thread and further reinforced with fabric backing and adhesive to create the most usable and.

Smyth sewn binding machine.

Some books that.

Is a market leader in the design planning and construction of bookbinding machines and in finding solutions for sewing and binding printed books in both off set and digital versions with a vertical focus on thread book sewing machines gathering machines back gluing lines case makers and book finishing solutions also for short run books on demand.

Smyth sewn binding is a technique that involves sewing the pages into the book physically with binding thread.

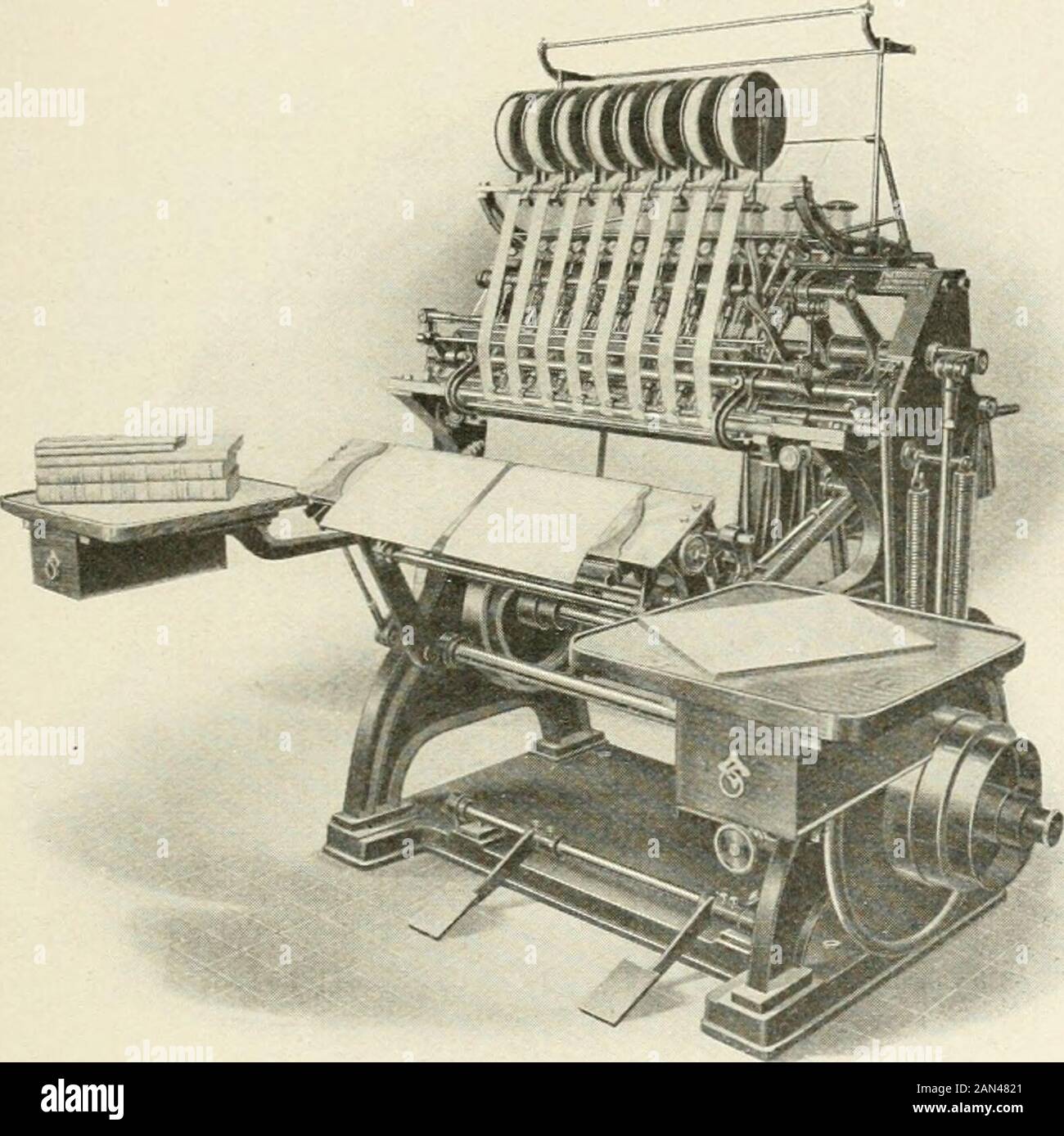

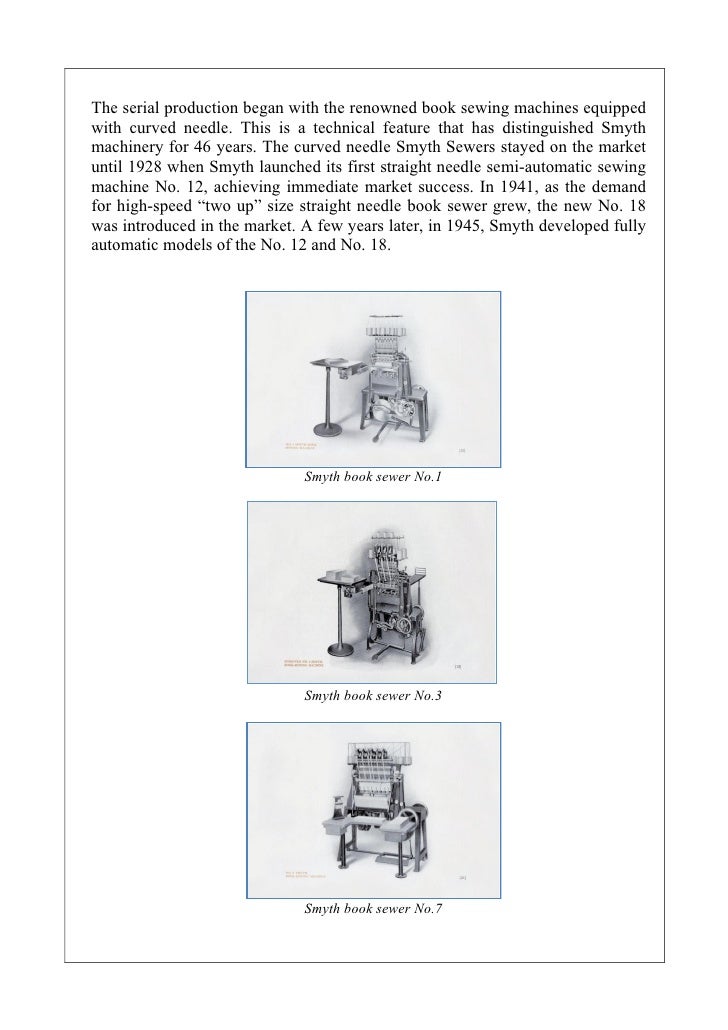

In 1882 the smyth manufacturing company in hartford ct began the production of the sewing machine resulting in significant progress in bookbinding technology hence the term smyth sewn.

There are different types of smyth sewn machines both manual semi automatic and fully automated.

Pages sewn together before assembly.

The initial production of book sewing machines began in 1871 when david mcconnell smyth obtained his first patent.

Smyth sewing is a method of book binding where groups of folded pages referred to as signatures are stitched together using binder thread.

If you page through a smyth sewn.

Smyth sewn binding specifications.

Once sewn in fabric backing and various adhesives reinforce the pages ensuring a lasting hold.

Each folded signature is sewn together individually with multiple stiches and then joined with other signatures to create the complete book block.