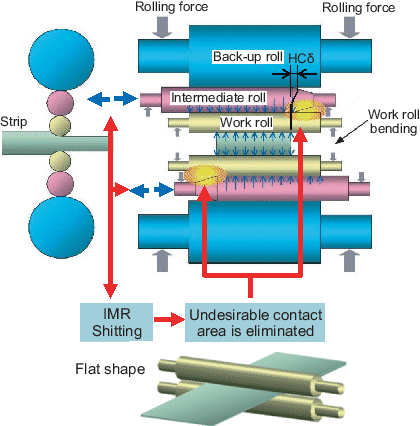

Reversing mills are designed so that the steel can be reversed and pushed back through the rollers which are brought closer together each time until the desired thickness is achieved.

Small cold rolling mill.

The most common configuration is the single reversing mill.

That explains why we design our cold rolling mills to be just as versatile.

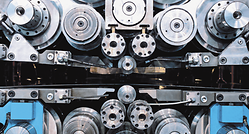

Rolling mill can b e designed as 20 hi 12hi 8 hi 6 hi 4 hi and 2 hi rolling mills.

Enjoy the videos and music you love upload original content and share it all with friends family and the world on youtube.

Due to government environmental protection and deproductivity action a lot of good machines are stopped we can find you second hand rolling mills with good condition and.

69 davy mckee aluminum cold rolling mill.

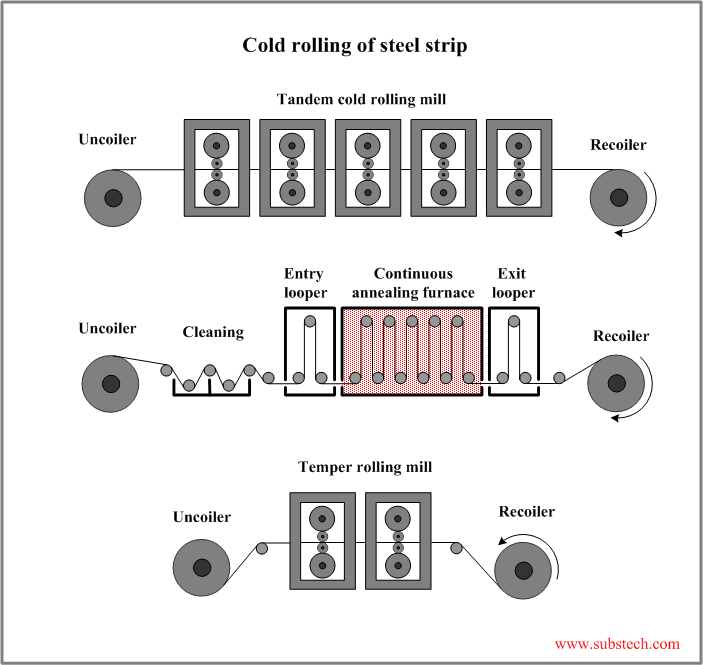

Cold rolling is a process by which the sheet metal or strip stock is introduced between rollers and then compressed and squeezed.

Davy mckee manufacturer davy mckee new 1989 type of mill.

Multi stand mills have three to six pairs of.

Tandem mills can be either of hot or cold rolling mill types.

Cold rolling mill machine sale.

This is of paramount importance due to the near 100 up time requirements of modern cold rolling mills and to ensure precise and correct product thickness prior to final processing and shipment to the customer.

Single stand 4 hi cold mill hand of mill right to left material.

In a traditional rolling mill rolling is done in several passes but in tandem mill there are several stands 2 stands and reductions take place successively.

Steel coil aluminum coil copper coil your application we also provide high precision cold rolling mill and hot rolling mill you need better cold rolling mill at good price.

The number of stands ranges from 2 to 18.

Accurate length and speed measurements for the cold rolling mill requires a high performance and reliable gauging system.

The amount of strain introd.

Opting for our efficient plant designs means you can rely on achieving the precise strip reduction and high surface qualities you want.

The cold rolling mill is usually fitted with thickness gauges that check the steel as it comes out of the rollers.

What s important to you are not only high flexibility and product quality but also sustained cost effective operation of your plants.