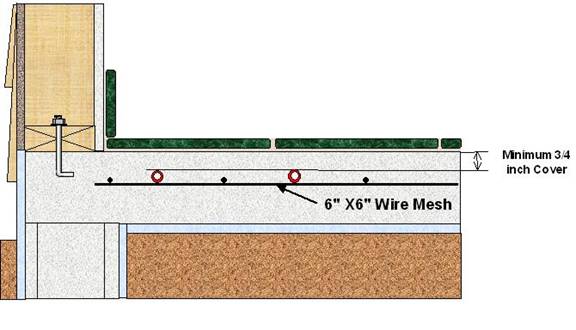

Designed to receive 6 8 and 10 wire mesh the flexible plastic support chair mesh up helps solve the problems of concrete slabs at grade will.

Problems with tie tubing to wire mesh in floor heating.

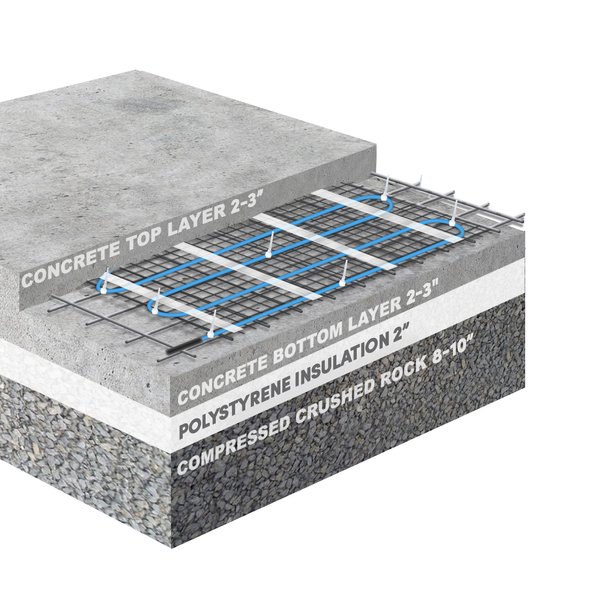

Sometimes the tubing and reinforcing mesh it is attached to gets lifted into the thickness of the slab as the concrete is placed.

Much cheaper and faster than zip ties and no ends to deal with.

Tie the tubing spaced 9 inches on center when you use the wire mesh sheets they are spaced every 6 inches so you can run the tubing next to the wall and use the mesh to guide you along.

Pex bend supports used to provide smooth 90 degree bends of pex pipe where needed.

Help to support mesh above the membrane before and during pouring.

Anyone who has installed hydronic floor heating has likely watched as his or her neatly placed tubing circuits get buried in concrete.

We use mesh pedestals and zip tie the pex to the top of mesh.

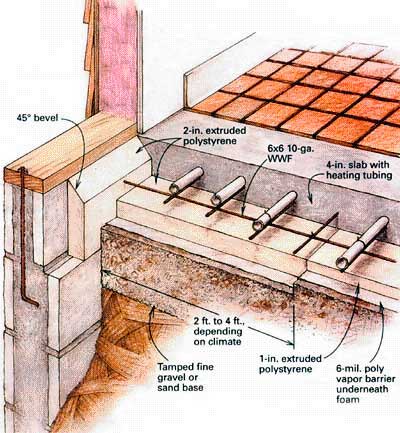

Now my heating contractor tells me that he prefers to use staples to hold the pex to the 2 insulation.

We tied our pex tubing to the wire mesh.

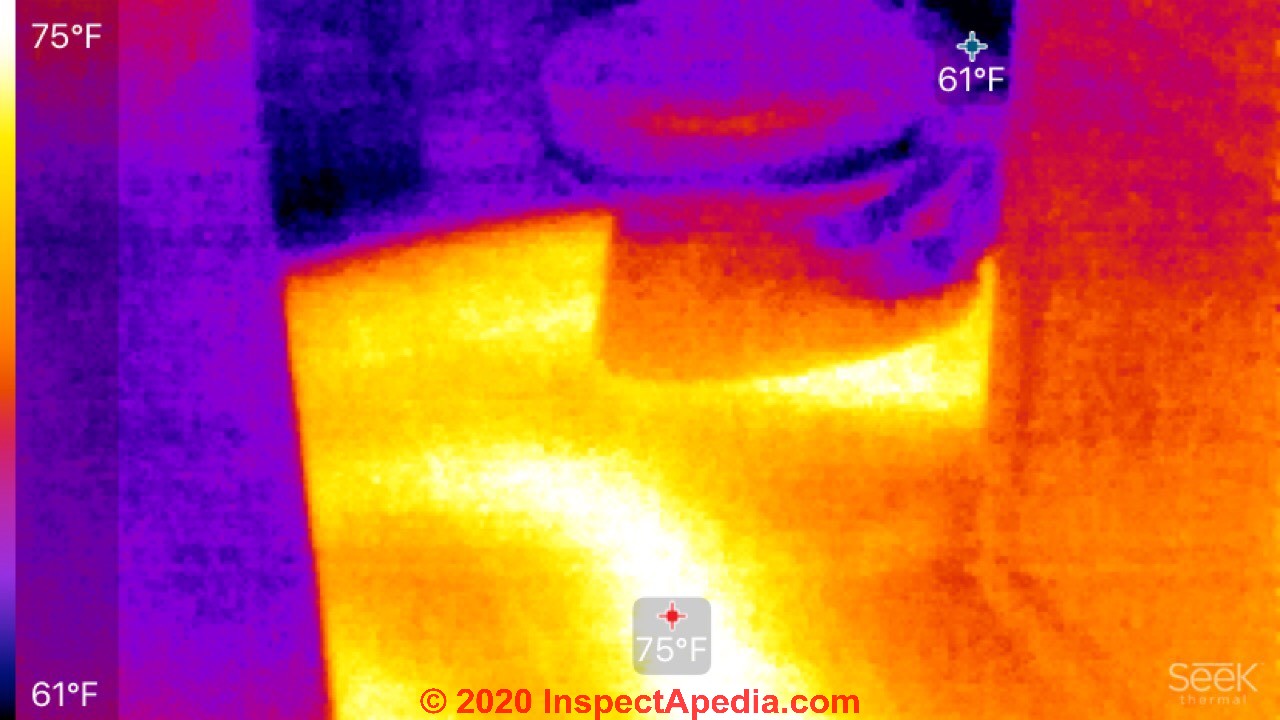

There are two types of radiant floor heating electric and water based systems.

We like putting the pex on top of the mesh because this makes it easier to repair any pex that gets damaged during the pour or that develops a leak sometime in the future.

Much like you would tie a bread bag.

Both provide heating in a room from the floor up for consistent efficient warmth.

Guys that tie rebar for bridges or swimming pools are incrediably fast with coiled wire.

Other times the masons trample over the tubing and mesh as if it is not even there.

Wire mesh clips used to secure 1 2 pex on top of wire mesh used to reinforce the slab.

Staple nail and screw down clips allow the installer to hold tubing to wood floors joists and studs.

Using the outside edge of the mesh come over a square and a half and then tie tubing approximately every 1 2 feet keeping it as straight as possible.

Regular tie wire in a dispensor on you belt is fast and quick if you have ever watched a pro use one.

Metal bend supports are most common for concrete slabs.

Clips for hold tubing down to rewire or rebar in radiant slabs greatly speed up a radiant project.

These clips are removable and can slide along the wire to adjust tubing spacing as needed.

The hydronic heating tubing can be fastened directly onto the wire mesh with zip ties wire ties or specialized tie systems with an automated tool.

This works well if you use equipment and have a crew that can pour the slab without trampling the pex mesh.

Aid in getting the mesh off the ground.

And since they are clips they allow the tubing to be repositioned for better coverage.

I buy 7 bar ties in rolls of 5000.

Concrete floor slabs in shops and garages typically carry heavier loads which is why these concrete slabs typically get reinforced with wire mesh.

:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/19490628/radiant_systems_02.jpg)