Banagher precast concrete offsite precast building solutions include but are not limited to precast flooring double tees stairs walls elevator cores beams façade panels bespoke and.

Precast concrete floor slabs ontario.

Our ontario operation has been supplying precast concrete to the canadian and northeastern u s.

Our engineered total precast structures combine hollowcore flooring wall panels double tees.

One stop provider for all concrete requirements.

Local precasters can help determine which sizes shapes and styles of components will best suit.

Spancrete hollowcore precast concrete planks slabs are fire resistant reduce weight and costs.

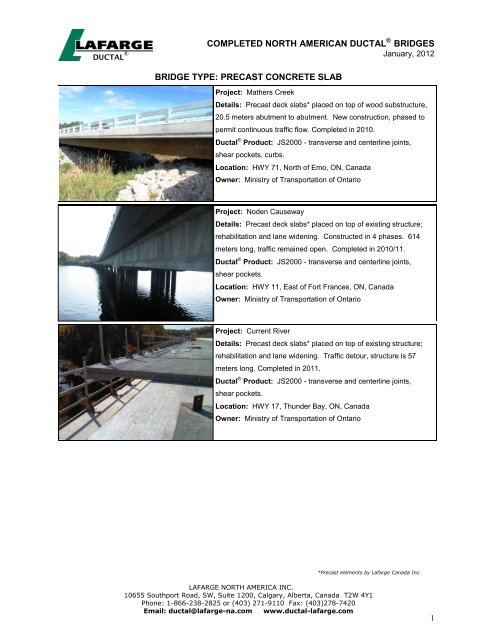

Lafarge precast concrete hollowcore slabs.

Fritz alder precast introduces the world s most advanced technology shear compaction to the ontario market shear compaction eliminates vibrating in the extruder resulting in controlled consistency between slabs and greatly reducing differential camber.

Learn more and see projects with hollowcore slabs.

Since 1948 hy grade precast concrete has been recognized as a company with strong integrity and a reputation for standing behind their commitments.

The keegan precast omnia flooring system is suitable for concrete steel and masonry building structures.

The omnia slab is a reinforced precast concrete slab which incorporates a lattice girder to provide stiffness and facilitate the placement of the top mesh.

Hollowcore is an extruded prestressed concrete slab with continuous voids to reduce weight and cost.

As part of the con cast pipe group of companies we continue to serve customers in the ontario and new york state marketplace with exceptional innovative products including stairs systems modular.

It is primarily used as a floor and roof deck system.

Precast concrete hollowcore slab flooring units provide long spans with cross sections that reduce the height of the building saving material cost and their inorganic composition enhances fire protection.

Slabs can be cantilevered up to 1 8 m to form exterior balconies.

Servicing the commercial.

It is used in many different building systems.

Our state of the art facility and hollowcore equipment provides maximum flexibility with sections strand patterns and.

Our precast manufacturing plants include over 340 000 square feet on 175 acres in southwestern ontario what we do.

Choosing precast over traditional in situ can lead to a reduction of up to 60 of manpower required on site and save up to 30 in construction time.

Construction rates of 1 floors per week and better are often achieved.

Bearing walls may be of masonry precast concrete or cast in place construction.